Blog

Difference between electrogalvanizing and hot-dip galvanizing

What is the difference between electrogalvanizing and hot-dip galvanizing?

Let us show you the differences, as well as the advantages and disadvantages of both methods.

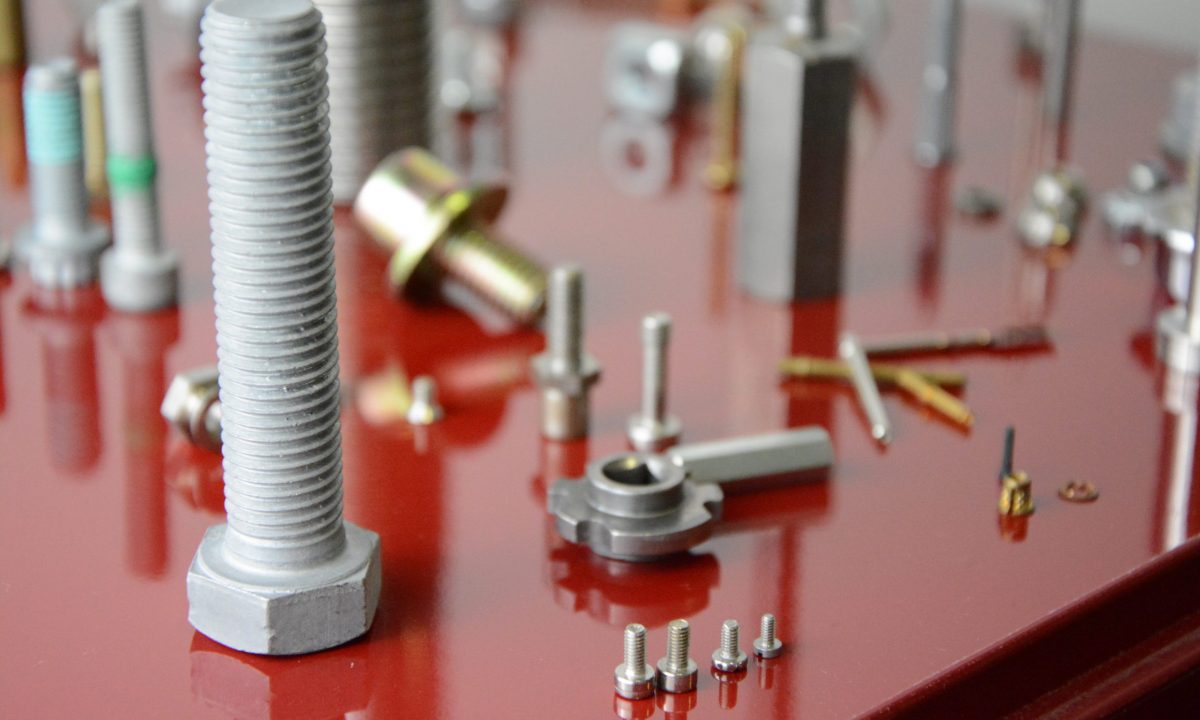

Steel fasteners can be coated with zinc to protect them from corrosion. Because there are different procedures, we will introduce you to the most common methods.

What happens during galvanizing?

The items to be processed are placed in a bath. Zinc is transferred to the uncoated pieces using direct current. The anode is usually pure zinc, the cathode(s) in this case are the fasteners to be coated. The zinc particles are detached from the pure zinc by the current flowing in the electrolyte bath and coat the piece. The length of time in which the parts take a “bath” determines the thickness of the applied layer. The longer the product is in the bath, the thicker the zinc coating. This makes it possible to determine very precisely how thick the layer will be. The standard layer thickness is between 5-8 µm. After treatment, a passivation / chromate coating can be applied to add more protection from corrosion.

Other coatings besides zinc are also used:

– Nickel

– Tin

– Silver

– and many others.

What about hot-dip galvanizing?

In hot-dip galvanizing, the fasteners are placed in a bath (usually in a basket) of pure liquid zinc at a temperature of approximately 530°C. This creates a resistant alloy layer of iron and zinc, over which the pure zinc layer is deposited. The parts are then placed in a centrifuge. If this important step is omitted, the bolts and nuts can no longer be properly fitted together. This is because too much zinc in the threads can make assembly difficult. The excess liquid material is removed in the centrifuge, and the result nuts and screws that can be easily fitted together. However, the thickness of the layer cannot be controlled as precisely in this process as it can with electrogalvanizing. Depending on the requirements, the thickness of the layer can be between 5-40 µm.

Conclusion:

In general, hot-dip galvanized goods offer better protection from corrosion because of the alloy layer and the thicker zinc coating. However, electrogalvanizing is sufficient in most cases.

And of course, we offer you all the above-mentioned coatings.

Please contact us for more information.